When it comes to creating efficiencies in construction, BIM software plays a major role. BIM, or building information modeling, has taken CAD blue prints to a whole new level; a much more efficient level leading to cost savings. BIM is a powerful tool. Like any power tool, the end product is dependent on the user. “It’s not magic,” said Mindie Nauman, senior architect with Strang, Inc., Madison. “The output is as good as the input. It’s as accurate as what’s being put in,” she said. With the right input, construction drawings virtually come alive with BIM.

“Imagine if I have a flat set of line drawings from the structural engineer whenever he prints that and sends it to me and compare that to a 3-D BIM model,” said Nauman, NCARB, who has been using BIM for 12 years. “All of a sudden, not only can I look at a structural beam in a plan, but I can cut sections throughout the building to see if it’s running into anything and see where it is in comparison to light fixtures.”

BIM is not just for architects. Nauman, who swears by the BIM software Autodesk Revit, contends it is well worth the investment for construction coordination and clash detection. BIM is extremely valuable for preconstruction meetings, where all subcontractors are assembled in one room with possibly architects and engineers. When the project is put up on a screen, everyone can see any potential conflicts.

“It could be like, hey, I’ve got sprinkler pipes running through duct work here. This is a problem,” Nauman said.

With BIM, it’s not a huge problem because it’s remedied before anyone is on the job site installing materials. The huge cost of ripping material out and having to reorder and reconstruct is now eliminated, not to mention the preservation of scheduling.

“There’s just a lot of issues, where if you work it out virtually beforehand, which is what the software allows you to do, it saves you a lot of time and money. That’s why contractors really like it,” Nauman said. “It’s a huge savings because there’s going to be conflicts on every job.” Traditionally, BIM was only used by larger contractors working on larger projects because there were greater economies of scale savings. Now, roughly 8 in 10 contractors are estimated to be using BIM for at least some projects. Nauman suggests contractors who are not using it should get on board. “We kind of cringe when we have to work with an engineering consultant or contractor asking us for CAD drawings. In the back of our minds, they may as well have said, ‘Send us a fax.’”

Contractors are apprehensive about using BIM, in part, because it’s not cheap. The cost is about $6,000 per seat to use, not to mention the investment in potential hardware investment and training time. Construction teams are becoming more proficient at using BIM, which reduces the upfront investment cost. Nauman said she has worked with contractors, who will convert basic CAD plans from an architect or engineer into BIM because of the potential payback with clash detection.

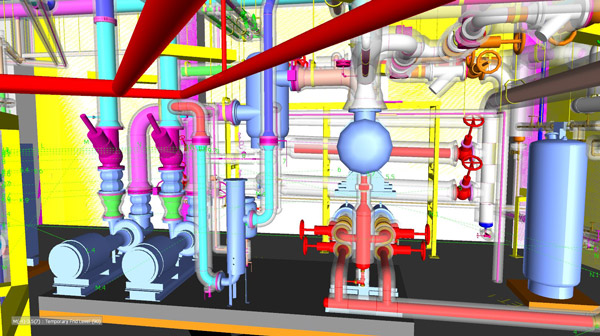

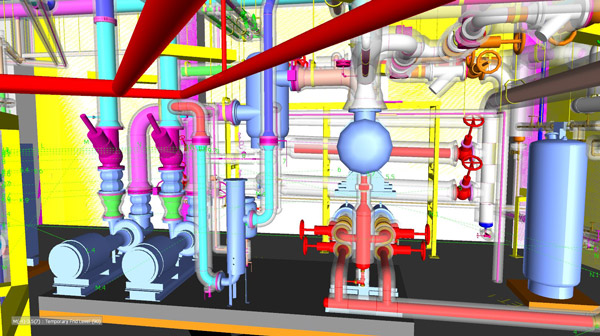

BIM can be especially valuable for mechanical contractors who deal with crowded mechanical rooms with ducts twisting and turning one over the other. That is often difficult to read on a floor plan but when you’re using a 3-D model, you can really see it.

“It allows us to avoid mistakes,” said Melody Doyle, construction director with NAMI, DeForest. “We are essentially preventing clashes and creating efficiencies when the building process begins. It also allows us to build faster because of more efficient fabrication time. The process has reduced construction time by eliminating all the measuring in the field prior to fabrication because fabrication comes off the model,” Doyle said. “Everyone wants things completed at warped speed. The prebuilding allows you to build faster.”

While Revit is widely used for construction design, and more specifically, mechanical design, Doyle points out it is not good for the fabrication process, especially with pipe fittings and sheet metal fittings and exacting points. NAMI combines the benefits of its Autodesk software and Revit models through Navisworks, software that combines various file formats for the full model experience and an accurate fabrication process. Another benefit to BIM is contractors having advanced knowledge of their respective space and location of materials so contractors aren’t arguing about where installs go. Doyle points out this is particularly useful for high-density projects like hospitals or labs, which require so much more mechanical work and reduced options. It also allows contractors to work from the top down in many situations. NAMI also employs a robotic-type tool call a Trimble. Using the BIM software, the Trimble can locate all points on the deck of a project where hangers will be. Knowing this in advance of concrete pours eliminates the need for drilling hanger points.

As far as other trades, sprinkler fitters have been using BIM the longest. Doyle said plumbers tend to like BIM because pitch or elevation can be seen virtually in the model. Electricians don’t have as great a need for BIM because they can install materials in tighter spaces. There’s one benefit many contractors are not tapping into, according to Nauman. “If the model is done accurately, you can actually call out the different materials and use it for cost estimating as well. You can pull a bill of materials off it, which is very handy,” she added. It eliminates the need to sit down with the plan and a bunch of different colored highlighters to dimension everything. BIM is not just a design tool, however. Nauman said the “information” component of BIM should not be overlooked. “Most people think of BIM as being 3-D, which is a nice feature, but the most important point is the information behind it.”

“BIM is object based instead of line based. So, you put a cabinet in and you can be as generic or as specific as you want. So, when you select that cabinet, it could tell you the manufacturer, the size, the link to the manufacturers website … you can have cost information on it. It’s all really information rich besides giving the client a 3-D view,” Nauman said.

The information component of BIM also allows owners to have easy access to materials should they need to be replaced in the future. Some owners ask for the actual BIM model to keep track of the different brands of carpet or ceiling tiles for replacements in the future. BIM brings all details of the project into one place for full integration into a 3-D model. It brings many layers of data together to enhance the workflow of the construction project. With BIM, the project is built twice; once in a virtual world and once in the real world. Contractors who aren’t using BIM need to get into these “worlds” to experience the many efficiencies and other benefits it provides.

By Kyle Schwarm